The hierarchy of controls used in risk management starts with the elimination of risk. If a hazard or risk is removed then this is the best way to prevent harm. Where it isn’t possible to eliminate the risk then opportunities to substitute it for a less harmful alternative should be sought.

The next tool in our armoury to minimise risk is to introduce engineering controls. These are the next step as they generally remain giving protection without having to put them in place each time. They must be checked that they are in place and effective on a regular basis. FISA released

‘Technical Note 003’ last year to help guide us on inspection.

The fourth step in the hierarchy are procedural controls such as safe system of work, training etc. These rely on us following them to ensure we remain safe at work.

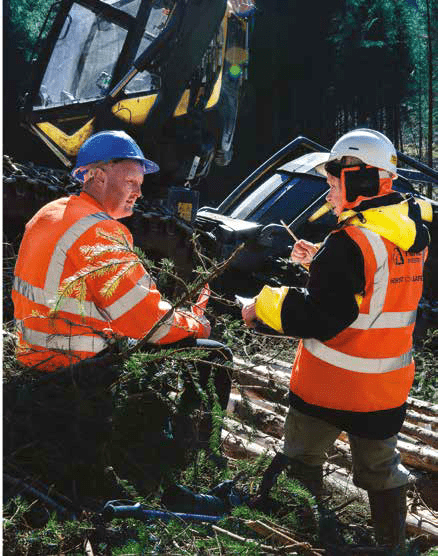

The final option to help minimise any residual risk is PPE. The aim of all of the above steps is to reduce the risk of injury as far as reasonably practicable, but in many instances there remains residual risk. PPE is used to mitigate this residual risk. By its very nature, PPE is Personal, it is one way we can personally reduce our exposure to risk and prevent injury and harm. Yet we too often see people not wearing the PPE that has been provided to them.

On a recent site visit one of our managers discovered an operator using a chainsaw without wearing chainsaw protective trousers.

We should, where practicable, mechanise operations to reduce chainsaw use There are many procedural controls with training, competence and techniques etc. However, there remains considerable residual risk from the saw when in use. Chainsaw trousers and boots are the last line of defence.

A recent incident left an operator with a small wound when the saw they were using came into contact with their chainsaw trousers. The trousers did their job, stopping the saw before the injury became more severe. No one intends for an incident, so we have to be prepared at all times.

We should all look for ways to move our risk control up the hierarchy – look for alternative safer work methods, ensure engineering controls are in place, follow procedures and training, or suggest improvements, before we reach for the PPE, BUT, where it is required could you look your family in the eye and tell them your injury and potential loss of wages could have been avoided if you’d worn your PPE?